As part of the three-story addition to the Cancer Center building was tying the HVAC into the main campus central utility plant (CUP).

This portion of our scope required upgrading the central utility plant by replacing and installing additional cooling towers, adding a new chiller, and tying the main chilled water and hot water distribution piping into the Cancer Center.

After starting the project, it was discovered that no isolation valves were installed in the chilled water piping when the CUP was initially built. This would have required shutting down the entire hospital, draining all the treated water within the chilled water lines, refilling the system, and treating the water when the piping was finished.

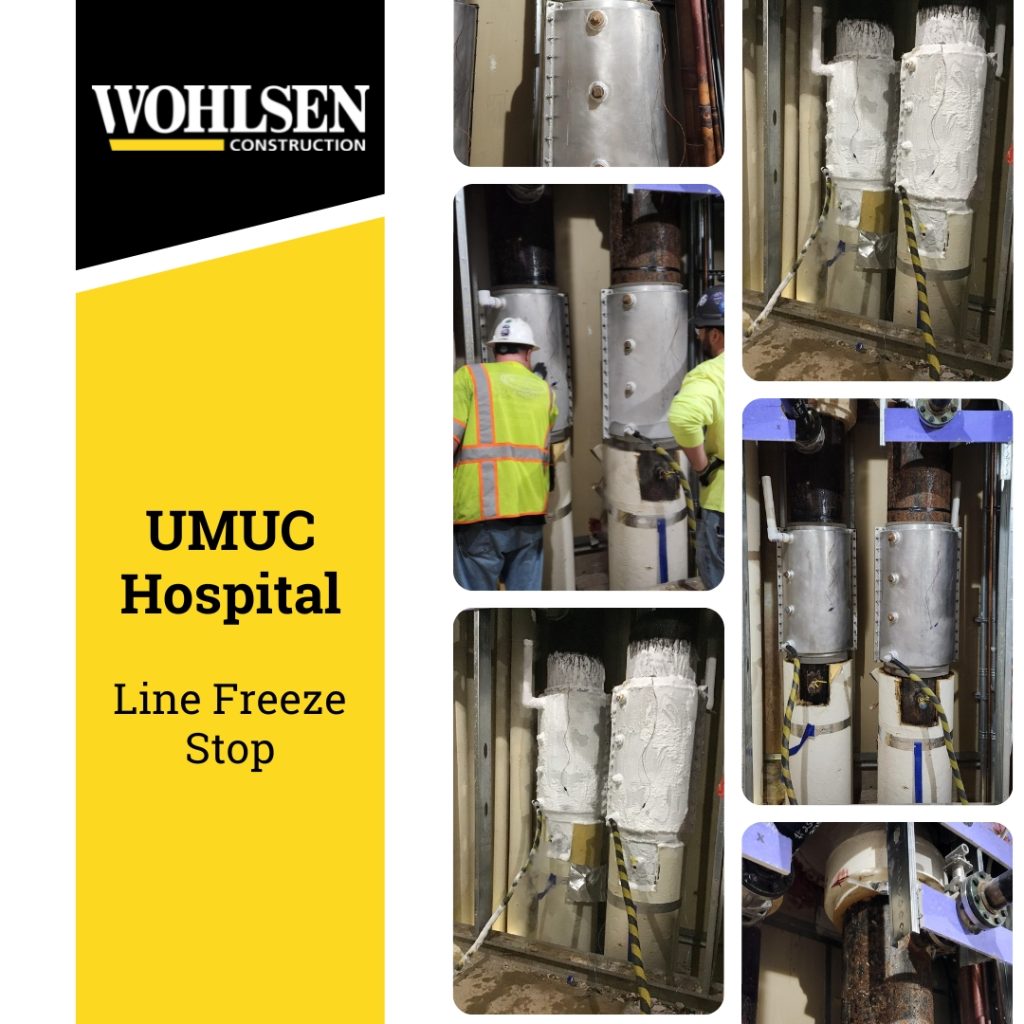

Wohlsen’s MEP team proposed a freeze stop in the 18-inch main chilled water lines so the piping could be tied in with minimal downtime.

After months of coordination and planning with the hospital, this approach helped us shut down within 48 hours instead of two weeks and save draining and filling an estimated 25,000 gallons of water from the chilled water system.